Solar Ground Screws

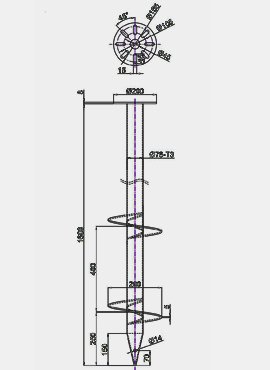

- ground screw size:standard or custom

- material:Q235,ASTM A63,etc.

- Anti-Corrosive:Hot Dip Galvanized

- Warranty: 10 years

- Installation Site:all type of soil

- Delivery time:About 20 Days

- Certification:CE,ISO9001/14001/45001,Rohs,etc

- Standards:GB50021-200/GB50007-2002/GB50011-2001,etc

Benefit

1. Strong bearing capacity: The welded spiral blade of the ground pile increases its own bearing capacity.

2. Easy construction: No need to dig or pour cement, simply use a pile driver to drive into the ground. Not damaging the environment, high efficiency.

3. Strong applicability: No matter what kind of soil, suitable spiral piles can be found.

4. Recyclable: Spiral ground stakes can be unscrewed for recycling when no longer needed, reducing waste.

5. Green and environmentally friendly: Spiral ground piles do not pollute, do not require excavation, and do not damage surface vegetation.

6. Good corrosion resistance: The hot-dip galvanized surface can resist acid, moisture, and salt alkali corrosion. Long service life.

7. Low cost: The material of spiral ground piles is mainly carbon steel, which greatly reduces the cost for customers.

What is solar ground screws?

Photovoltaic Steel Helical Ground Screw

A better quality foundation

A type of helical ground screw made from round steel tubing that has been reprocessed, welded, and hot-dipped galvanised. These days, ground screws are used all over the world to build strong foundations that last a long time. They can be used for any kind of building or landscape. The design of JUCC’s solution is simple: it complies with building codes, is easy and economical to install, and can be constructed in just a few hours, not days or weeks.

Ground screws are a great way to build things in hard-to-reach places. They are better for the environment than using concrete and deep foundations. Jucai Huixin can help you with all your project needs. We offer ground anchors and ground screw anchors, as well as customised solutions to meet your needs. Our ground anchors are the best, and we offer great customer service. This has made us a leader in the industry.

Product By Features

At Jucai Huixin, solar ground screws can be classified into steel spiral ground piles and aluminum spiral ground piles according to their materials.

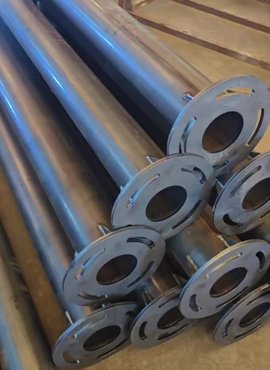

If classified by installation method, photovoltaic spiral ground piles can be divided into direct buried spiral ground piles and flange spiral ground piles.

If classified according to bearing capacity, photovoltaic spiral ground piles can be divided into lightweight spiral ground piles and heavy-duty spiral ground piles.

If classified according to the shape, PV Helical Ground Stakes can also be divided into single line type, multi-line type, cone type, U type and other product types.

Mainly used for fences, barriers and other occasions, it is connected by U-shaped plates. This type of ground nail is convenient to connect, easy to fix, and firmly connected, but the price is slightly higher.

The installation height can be adjusted by fixing the flange to the ground. Suitable for situations with uneven terrain or requiring specific installation heights.

Lightweight, easy to transport and install. Good corrosion resistance, suitable for harsh environments such as seaside and humid conditions.

Has high strength and load-bearing capacity, suitable for large-scale photovoltaic power generation projects. The surface has undergone anti-corrosion treatment, which can extend its service life.

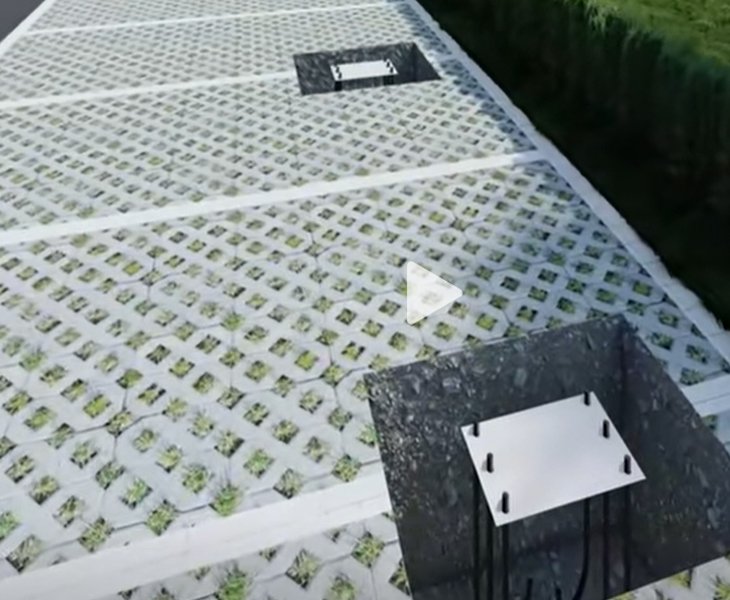

Fried Dough Twists Solar Ground Screw is a new type of infrastructure combining aesthetics and technology. Its core advantage lies in the ability to fully utilize land resources for energy development and application.

Unflanged PV Screw Ground Stakes are mainly used for fixing PV mounts to ensure the stable operation of PV systems.

This type of ground pile has two spiral blades, which have a larger contact area and stronger grip, making it suitable for situations with poor soil conditions or the need to withstand large loads

It is mainly used for fixing and stabilising small photovoltaic systems. The surface can be hot-dip galvanised and then painted.

Solar Ground Screw

At Jucai Huixin, Solar ground screw making process mainly have those steps below:

The manufacturing materials for photovoltaic spiral ground piles are selected high-quality circular steel pipes.

Cut the round tube into customized sizes according to customer requirements.

Heat the end of the circular tube at high temperature.

This step involves tapering the top of the ground stake to form a pointed shape.

This step is to clean the rust and other impurities on the surface of the ground pile.

This step is to perform hot-dip galvanizing surface treatment on the ground piles to make them more corrosion-resistant.

According to the storage standards, neatly code and place it in the ground pile warehouse.

Application

The application scenarios of spiral photovoltaic ground piles are very wide, mainly including the following:

Solar ground screw is widely used for large scale agricultural photovoltaic power station.

Solar ground screw is widely used for Large scale industrial and commercial photovoltaic power station.

Solar ground screw is widely used for Distributed Photovoltaic Project.

Solar ground screw is widely used for Desert Photovoltaic Power Station.

Overview

As a large-scale source factory for the production of photovoltaic ground piles, Jucai Huixin can ensure the product quality of photovoltaic ground piles at the production end and save customers money in all aspects. The advantages are mainly reflected in the following aspects.

Jucai Huixin is AAA China Integrity Management Enterprise.

The total installed capacity has reached 5GW.

Focusing on photovoltaic brackets, serving the green new energy industry

Jucai Huixin is Innovative technology enterprise.

Economic benefits of photovoltaic power generation

Jucai Huixin Total land area of 30000 square meters

Jucai Huixin can provide one-stop procurement services for photovoltaic users.

Jucai Huixin Meets ISO9001,ISO14001,ISO45001,Rohs,etc.

Solar Ground Screw Installation Steps

Before installing spiral ground piles, it is necessary to conduct geological surveys to understand information such as soil conditions, groundwater level, and bearing capacity.

Determine the diameter, length, pitch, material, and quantity of spiral ground piles based on engineering requirements and geological conditions.

Design construction drawings to clarify the position, angle, and depth of each spiral pile.

Prepare suitable installation equipment, such as a rotary drilling rig.

Clean up the installation area at the construction site to ensure that there are no debris or obstacles.

Use a rotary drilling rig to drill holes at designated locations, and the depth and diameter of the holes should meet the design requirements.

How To Install A Solar Ground Screw?

The installation of photovoltaic spiral ground piles can be roughly divided into three simple steps:

- Pile driver preparation

- Lift the manufactured spiral ground pile into the borehole, ensuring that the ground pile is vertical.

- Use specialized tools or machinery to slowly screw the ground pile into the ground until it reaches the design depth.

How To Install Anchor Bolt For Solar Carport?

For the foundation installation of photovoltaic carports, we strictly follow the relevant standard procedures. The following are the main installation steps:

1. Firstly, according to the requirements of the drawing, groove the foundation of the foundation in advance,

2. Then place the pre welded embedded bolts into the pre excavated foundation pit according to the size.

3. Then pour the pre embedded bolts with concrete and fix the adjusting nuts in advance.

Resource

Partners, here is the company’s product catalogue of Jucai Huixin, click can be downloaded!

Partners, here is an electronic catalog of all the photovoltaic spiral ground piles that Jucai Huixin can produce and supply. Click to download.

Friends, this is the YouTube channel of Jucai Huixin, which contains our most comprehensive installation and usage videos.

More About Our Product

Partners, here is an electronic parameter table for the products you want.

- Product Data Sheet

- After-Sales Service

- Custom Solar Ground Screw

| name | describe | diameter(mm) | length(mm) | Material | picture |

| 1 | Screw pile without flange 76 * 1200 (welding 3 nuts) | 76 | 1200 | Q235 hot dip galvanized | |

| 2 | Heightening pile with flange 60 * 600 (circular hole) | 60 | 600 | Q235 hot dip galvanized | |

| 3 | Heightening pile with flange 60 * 600 (plum blossom hole) | 60 | 600 | Q235 hot dip galvanized | |

| 4 | Heightening pile with flange 60 * 600 (4 holes) | 60 | 600 | Q235 hot dip galvanized | |

| 5 | Spiral pile with flange 76 * 1200 ~ 3000 (circular hole) | 76 | 1200~3000 | Q235 hot dip galvanized | |

| 6 | Spiral pile with flange 76 * 1200 ~ 3000 (plum blossom hole) | 76 | 1200~3000 | Q235 hot dip galvanized | |

| 7 | Spiral pile with flange 76 * 1200 ~ 3000 (4 holes) | 76 | 1200~3000 | Q235 hot dip galvanized | |

| 8 | Spiral pile with flange 89 * 1200 ~ 3000 (circular hole) | 89 | 1200~3000 | Q235 hot dip galvanized | |

| 9 | Spiral pile with flange 89 * 1200 ~ 3000 (plum blossom hole) | 89 | 1200~3000 | Q235 hot dip galvanized | |

| 10 | Spiral pile with flange 89 * 1200 ~ 3000 (4 holes) | 89 | 1200~3000 | Q235 hot dip galvanized |

Our photovoltaic spiral ground pile comes with a one-year warranty service after sale, provided that it is not damaged by human factors. During this period, if the product experiences quality problems such as cracking or disconnection, it can be replaced or repaired.

In addition, during the installation process, we provide customers with certain technical guidance and use remote video connections to teach them step-by-step how to operate.

Related Product

Jucai Huixin can produce all kinds of Single Axis Solar Tracking System.

Jucai Huixin can produce all kinds of Dual Axis Solar Tracking System.

If you have any problem about solar ground screw

please contact our sales manager quickly: admin@jchxsolar.com

We will provide you with a satisfactory response as soon as possible

Hexagon head cap screws.

Solar Ground screws can be installed significantly faster than concrete foundations

Use photovoltaic spiral ground piles combined with photovoltaic brackets and their supporting connectors to fix the photovoltaic panels.

75 years

They can carry considerable weight, often matching or exceeding the load-bearing capacity of concrete.